Consumers are demanding sustainable alternatives to plastic and polystyrene packaging and the momentum is only growing. One of the strongest solutions we have is moulded fibre (also known as moulded pulp) representing a versatile, compostable and all natural material perfect for a variety of packaging applications and industries.

Moulded fibre was first patented in 1903, making it technically even older than plastic. But what actually is it, how is it produced and what are the benefits of this over plastic?

What is it?

Moulded fibre is a sustainable packaging material commonly made from sources such as wood pulp, recycled newspaper, recycled cardboard, recycled kraft paper as well as plant materials such as bamboo, sugarcane bagasse, wheat straw and more. These plant materials usually come from crop waste.

How is it made?

- The raw materials go into a pulper and are blended with hot water which swells the fibres to create a watery mixture.

- The pulp exits out the bottom of a pulper through a filter which gets rid of contaminants and any plastics

- A vacuum then sucks the mixture onto formation moulds and water jets get rid of any excess mixture

- Transfer flats then move the formation moulds onto a conveyer

- A brush applies a water based lubricant so the moulds don’t stick

- The moulds then go into an oven so the water is evaporated and the fibres are bonded together to form a rigid material

Functional benefits of moulded fibre packaging

- It can form into a variety of shapes

- No assembly required

- It is highly protective as it can be moulded to carefully fit any products and hold it in place during transportation

- Unlike PVF or foam packaging, it is highly durable and won’t deform from high temperatures

Environmental benefits of moulded fibre packaging

- Largely made from crop waste which is widely available and often discarded

- Made from recycled paper materials reducing the number of trees that are needed for production

- Wood fibre is potentially a renewable resource when forests are properly managed

- Can easily be recycled again after its useful life-cycle

- Fibres used are biodegradable which reduces the hazard of littered items in wildlife

- Compostable as its made from plant products

- The perfect alternative to styrofoam which takes over 500 years to break down, uses 30% of the space in landfills and is made from non-renewable resources

- Zero manufacturing waste as all scraps are returned to the pulper

- No waste water in the manufacturing process- all water evaporates or is reused

Food packaging benefits of moulded fibre packaging

- Water and grease resistant

- Microwave and freezer save

- Provides effective insulation

Common uses

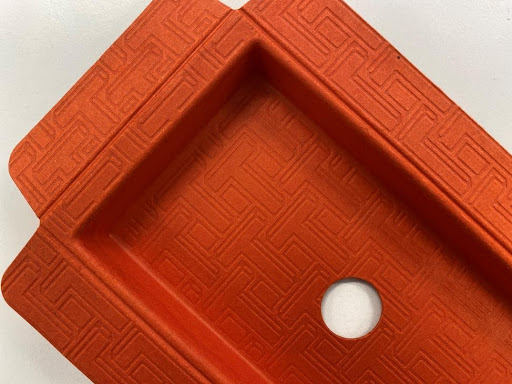

- Cosmetics packaging

- Technology packaging

- Wine and spirit bottles packaging

- Pharmaceutical packaging

- Jewellery packaging

- Confectionary packaging

- Chocolate packaging

- E-Commerce packaging

- Cushioning material for the protection of products during transportation

- Egg cartons

- Plates

- Bowls

- Clamshells

Our solution

Moulded fibre packaging removes a pain point for consumers as they don’t have to feel guilty about using wasteful packaging products. No eco-friendly business strategy is complete without using moulded fibre packaging due to its enormous range of environmental benefits.

The growing consumer demand for eco-packaging presents an opportunity for businesses to gain consumer trust and loyalty. Ecolution can service your business, no matter what industry you’re in by providing custom moulded fibre packaging products including boxes and inserts.

Check out our products below or contact us today to find out more.